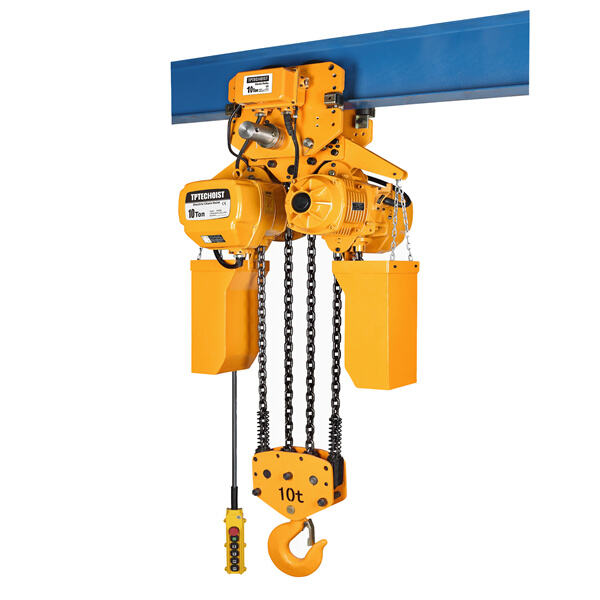

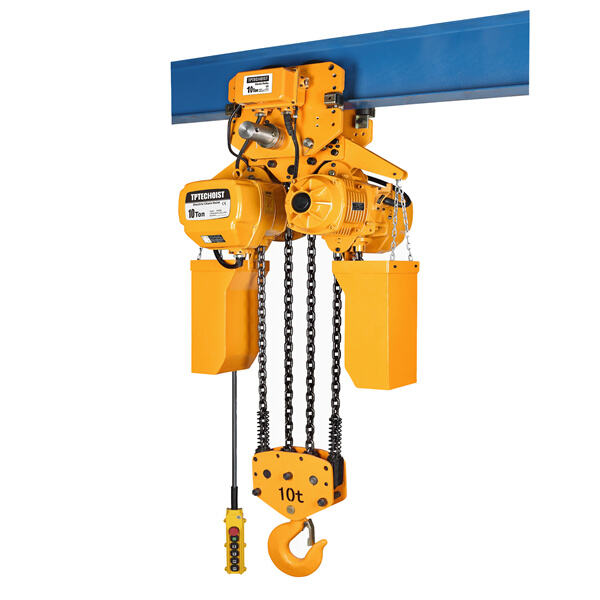

Ever wondered how really heavy things are lifted very high in the air? You may have watched a large construction crane hoist up heavy beams or small tow truck pull away car that broke down. Each of these devices is designed to lift heavy objects with a component called chain hoists. TPTECHOIST overhead chain hoist are manufactured in factories, and there has always been something quite interesting to come out of these chains -today we will learn more about what they do behind the scenes at a chain Oishi factory. I find it really interesting how these machines are built and how critical they make.

There are many different sizes, shapes of chain hoists and Table Of Content. The first step to construct a robust chain hoist is cutting steel bars into appropriate sizes by workers. This is crucial because its pieces must perfectly align together InfogetCurrent They heat the steel to thrush temperature (softening state) after cutting. Soft steel can then be formed into various components for the hoist. They whack the living shit out of it with giant hammers and other tools to make bendy steel shapes as needed.

Today a machine could be used to cut the steel into its correct dimensions, for example whereas before, it would have been done by the worker manually using a saw. This TPTECHOIST chain hoist replacement hooks change makes the production of chain hoists significantly faster. Welding the parts also has some new solutions; for example, using robots to help out. Because robots can weld faster and more precisely than humans, it's possible to make the hoists even better.

Welders Welders use a type of tool able to join separate pieces of metal. They have to be quite adept at what they do, as the welds need to be strong enough so that heavy weights can safely lifted with them. The hoist needs to work flawlessly and it could not without a good welder.

Inspectors – The job of these workers is to inspect each and every part of the hoist if they are find or suitable according to factory quality. They inspect the hoist to make sure there are no flaws or issues that may lead it to break down, so TPTECHOIST chain pulley block with geared trolley does not function as expected. These thorough checks ensure that each hoist is appropriate for use. Nature of work

TOPTECH is Chain hoist factory by profound understanding of engineering allowing us to create high-performance reliable crane systems Our product design and manufacturing process incorporates cutting-edge engineering techniques innovative technologies and intelligent control systems such as synchronized lifting and intelligent control systems

Chain hoist factory can tailor solutions that meet our customers particular operational needs. TOPTECH offers products tailored to meet the specific demands of various industries.

TOPTECH provides comprehensive services to help our clients to get the most value from their equipment. This includes maintenance, Chain hoist factory, spare parts and technical support. We also provide education and assistance to improve operational efficiency and safety.

Toptech Chain hoist factory a range of solutions to meet demands of material handling for small-scale workshops as well as large industrial facilities. Our product range comprises a variety of overhead cranes, gantry cranes and electric hoists, crane parts like end carriages, crane busbar and so on. Toptech will always be updated with the latest technology and innovative designs.