An overhead bridge crane, also known as a carrying machine could be very big and useful especially in places like factories and project sites. Their dream is that someday they will not only do these things, but also perform manual labour, haul rocks and scratch in the dirt. These TPTECHOIST wire rope Hoist crane are very powerful and have a lot of parts that all work together as a unit. So, lets now go a bit closer to how they work.

The overhead bridge crane consists of several main components. These include trolley hoist, end trucks, hoist, bridge girders for over head cranes and runway systems. Top running and under Slung. No parts are redundant: Each part has a specific function and without any one of them the crane would not work.

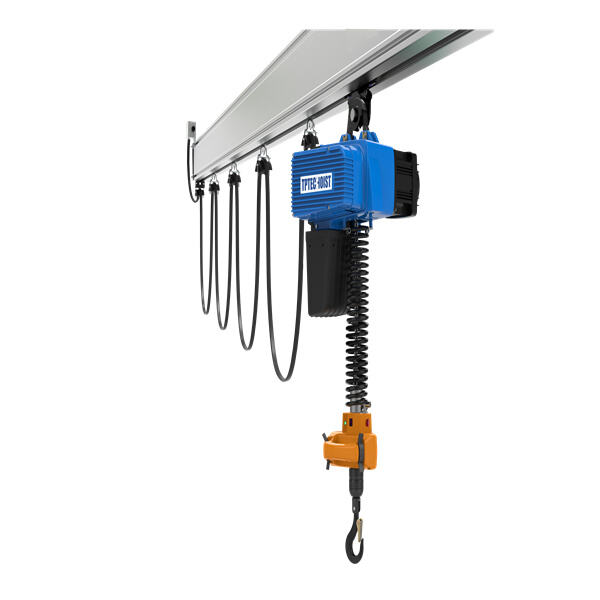

The trolley Hoist is one of the important components in a crane. It slides along the bridge girders, which are those heavy beams that support everything. The TPTECHOIST Crane components itself is attached to a chain or wire rope which is used for pulling heavy loads from the ground. Most Seen Lifting a very sophisticated process called an Iron hand suit. The end trucks are placed at the ends of the bridge girders. They help in assisting the crane as it moves across the tracks. The end trucks also include a set of wheeled mechanisms to aid in the crane rolling over uneven surfaces.

There is also the Hoist, an essential part of a crane that lifts and lowers loads. The TPTECHOIST overhead crane parts has the ability to also move items sided-to-sided, which works wonders for swing up placement. Bridge are the large, horizontal beams that provide structure which support and transport both the hoist along its length runway system as well as trolley movement.

Each rail is designed to fit securely into opposite channels that make up the system's runway gutters and on which a crane rides. These rails need to be strong, well maintained for the safe and efficient operation of a crane. The electrical system, too, is just as crucial minus the physical components. It powers the motors that move the overhead crane components and determine how each part of the crane will work.

It is very significant to maintain your overhead bridge crane. Regular checks and fixing make the crane accident free and also supports in smooth working of cranes. When parts of the crane are not adequately maintained, problems can arise that could cause harm to workers thereby being a safety hazard. This is why it is so important for those operating these crane components to be highly trained. One is they must be able to use the crane proficiently and also safely so that no accident can happen and other people around them stay safe.

TOPTECH has customized solutions to meet the particular requirements and Overhead bridge crane components requirements of our customers. We know the distinct requirements of various industries and provide customized products that align with specific functionality and standards of performance.

The expertise of TOPTECH's Overhead bridge crane components allows us to develop high-performance and robust crane systems that are reliable and high-performance The design and manufacturing process incorporates cutting-edge engineering principles advanced technologies as well as intelligent control systems such as the synchronized lifting system and the sophisticated control systems

Toptech Overhead bridge crane components a range of solutions to meet demands of material handling for small-scale workshops as well as large industrial facilities. Our product range comprises a variety of overhead cranes, gantry cranes and electric hoists, crane parts like end carriages, crane busbar and so on. Toptech will always be updated with the latest technology and innovative designs.

Overhead bridge crane components provide comprehensive support and services to help our customers maximize the use of our products. This includes electric hoist and cranes installation, maintenance, spare parts, and technical support, TOPTECH also offers training and consultancy services to improve the efficiency of operations and ensure safety and to ensure that the equipment performs at its best.