As one of the standard drafting units for CHINA CLEAN ROOM ELECTRIC HOISTS.

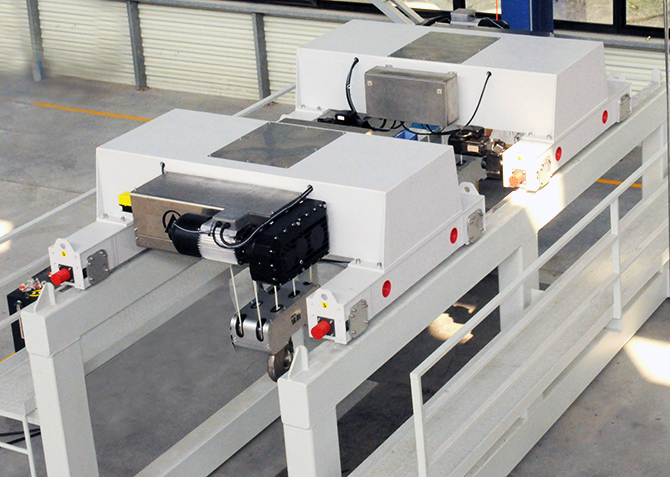

We proud to share to introduce you our TPTECHOIST electric hoist and cranes for dustless environments for you.

Refer to specialized lifting equipment designed to minimize the generation of dust and debris during operation, which is particularly important in environments where cleanliness is a priority. These types of hoists are often used in industries such as food processing, pharmaceuticals, and cleanroom environments where maintaining a dust-free atmosphere is crucial for safety, quality control, and compliance with industry standards.

1. Enclosed Motor and Gearing: The electric motor and gearing of dustless hoists are typically enclosed to prevent dust from entering the internal components, which could cause wear or malfunction. This design also prevents the escape of dust from the hoist itself during operation.

2. Smooth Surfaces: The hoist's surface is designed to be smooth and easy to clean, with no crevices where dust can accumulate.

3. Durable Materials: The materials used in the construction of dustless hoists are chosen for their durability and resistance to corrosion, which helps to reduce the generation of dust particles from flaking or corroding surfaces.

4. Sealed Swivel Hooks: The hooks or lifting attachments often have sealed bearings to reduce friction and prevent the generation of dust from metal-to-metal contact.

5. Low Vibration Operation: Dustless hoists are designed to operate with minimal vibration, which helps to reduce the disturbance of settled dust and the potential for airborne particles.

Dustless electric hoists are used in a variety of applications where clean and controlled environments are required. These include:

· Food Processing Plants: For lifting and moving raw ingredients, finished products, or heavy equipment without contaminating the food supply. 2

· Pharmaceutical Manufacturing: In the production and packaging of drugs, where airborne particles can affect the quality and safety of medications. 2

· Cleanrooms: In semiconductor manufacturing or research facilities where even the smallest particles can impact the quality of the product or experiment. 3

· Medical Facilities: For moving equipment and supplies in operating rooms or sterile environments where hygiene is critical

ISO 14644-1:2015 | ||||||

ISO Class (N) | Maximum Particles / m3 | |||||

≥0.1 μm | ≥0.2 μm | ≥0.3 μm | ≥0.5 μm | ≥1 μm | ≥5 μm | |

1 | 10 | 2 | ||||

2 | 100 | 24 | 10 | 4 | ||

3 | 1000 | 237 | 102 | 35 | 8 | |

4 | 10000 | 2370 | 1020 | 352 | 83 | |

5 | 100000 | 23700 | 10200 | 3520 | 832 | 29 |

6 | 1000000 | 237000 | 102000 | 35200 | 8320 | 293 |

7 | 352000 | 83200 | 2930 | |||

8 | 3520000 | 832000 | 29300 | |||

9 | 35200000 | 8320000 | 293000 |

Hot News

Hot News2024-02-05