Construir arranha-céus e içar objetos pesados e perigosos é um negócio difícil. É por isso que temos esses grandes guindastes de máquinas, o que torna seguro e fácil concluir essas tarefas. O guindaste mais comumente usado é o guindaste de ponte rolante. Este guindaste é equipado com um componente crucial conhecido como freio, que permite que ele opere com segurança e eficiência. Agora, vamos verificar mais sobre os freios de ponte rolante e por que eles são essenciais.

O freio da ponte rolante é um dos recursos essenciais de segurança associados a uma ponte rolante. Na verdade, esse é um recurso essencial para garantir que a ponte rolante pare quando necessário. Quando o operador (a pessoa que a dirige) quer parar de se mover, ele empurra uma alavanca especial: Essa alavanca puxaria manualmente e ativaria o sistema de freio. O freio em si tem pastilhas especializadas que seguram as rodas da ponte rolante. Se essas pastilhas seguram as rodas, elas não giram. Isso peças de ponte rolante a ação interrompe o movimento de um guindaste até que ele esteja pronto para ser levantado ou movido novamente.

Deslizamento do freio: isto componentes de ponte rolante o problema ocorre porque as sapatas de freio não estão agarrando a um grau que lhes permitiria segurar. Quando o guindaste processa um sinal de ensino, ele pode se mover, o que é perigoso.

Arrasto de freio - quando os freios não são liberados corretamente. Este TPTECHOIST pode fazer com que o guindaste continue se movendo quando um operador não os estiver usando; assim, torná-lo suscetível a acidentes.

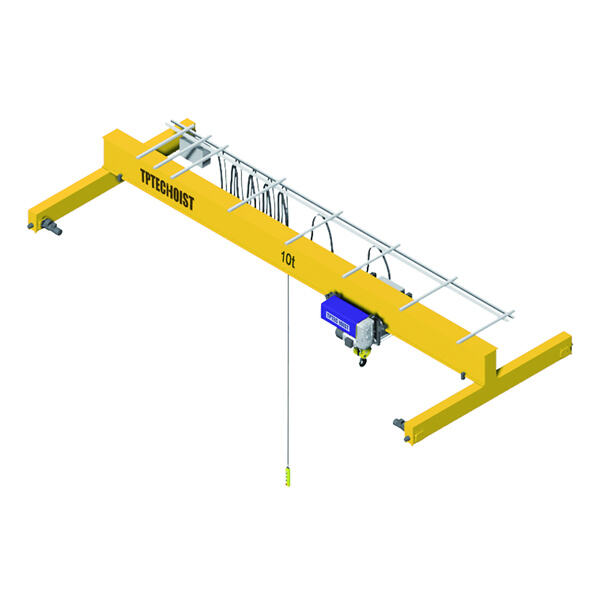

FREIOS DE PONTE ROLANTE - TPTECHOIST As pontes rolantes são peças vitais de máquinas na caminhões com ponta de guindaste indústria de construção.

Pontes rolantes são máquinas e, como todos os equipamentos que são sempre usados, precisam de manutenção regular. Uma das kits de ponte rolante maneiras de fazer isso é mantendo um sistema de freios funcionando bem. Verificar e inspecionar regularmente pode ajudar você a encontrar problemas antes que eles se tornem problemas maiores. Manter o sistema de freios limpo também é essencial, pois poeira, sujeira e detritos podem desgastar um conjunto de freios! Se você se concentrar neles com um pouco de TLC ocasionalmente, os freios do seu guindaste continuarão operando como deveriam por muitos anos.

Os freios de ponte rolante vêm em muitas formas, dependendo do uso pretendido. Quando se trata de sua decisão, há algumas coisas que você precisa considerar. É melhor pesar outros fatores, como o peso das cargas que você levantará, a rapidez com que o guindaste levanta etc., e em que tipo de ambiente você usará este guindaste? Por exemplo, se você estiver viajando com grandes caixas, então um sistema de freio potente e potente deve estar presente para manter sua bagagem no lugar sem escorregar ou arrastar para trás. Isto componentes do guindaste também significa que você vai querer um sistema de freio para operar em condições úmidas e empoeiradas, o que significa que ele deve ser projetado com resistência à corrosão e ao desgaste.

A TOPTECH pode fornecer soluções personalizadas que Overhead crane brake atendem aos requisitos operacionais específicos de nossos clientes. Conhecemos os requisitos distintos de diferentes indústrias e oferecemos produtos personalizados que atendem aos requisitos específicos de funcionalidade e desempenho.

A Toptech fornece uma gama de produtos para atender aos requisitos de manuseio de materiais para oficinas de freios de ponte rolante, bem como grandes instalações industriais. Nossa gama de produtos compreende uma variedade de pontes rolantes, guindastes de pórtico e talhas elétricas e componentes de guindaste, como carro de extremidade, barramento de guindaste e assim por diante. A Toptech está sempre atualizada com as últimas tecnologias e os designs mais inovadores.

Oferecemos uma gama de suporte e serviços para ajudar nossos clientes a obter o máximo de nossos produtos. Isso inclui instalação, manutenção, peças de reposição e assistência técnica de talhas e guindastes elétricos. A TOPTECH também oferece serviços de treinamento e consultoria para a segurança e eficiência da operação para garantir o desempenho ideal do equipamento.

A experiência em engenharia da TOPTECH nos permite projetar freios de ponte rolante de alto desempenho que são confiáveis e de alto desempenho. Nosso processo de design e fabricação de produtos incorpora conceitos de engenharia de ponta, bem como tecnologias de ponta e sistemas de controle inteligentes, como sistemas de controle sincronizados e inteligentes de elevação controlada.