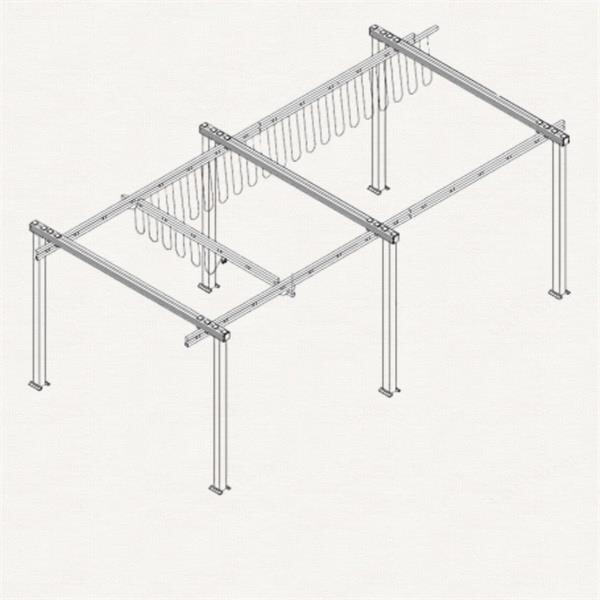

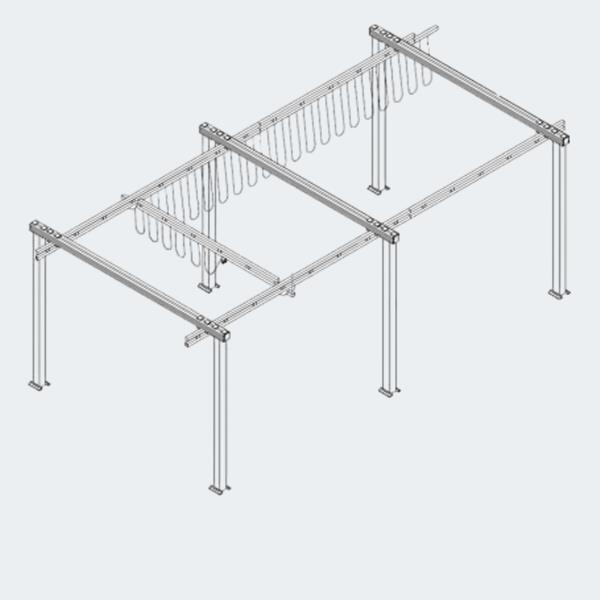

Girder cranes are powerful and large machines that lift heavy objects at construction sites and factories. A bridge, hoist, trolley, and runway are among the many essential components for these cranes. Bridge – The main component of the crane which is supported from a runway that travels along the length (called either an aisle or bay) in a building or area where it is operated. The bridge is the part that runs horizontally over the work area, while the hoist is the component capable of lifting and lowering heavy loads, and trolley is able to move the hoist parallel under a bridge. This movement is required to go from place to place for the heavy weights are

When it comes to the essence of girder cranes, this particular type of crane utilizes a series of pulleys, cables, or motors for moving and lifting heavy materials. The Wire rope hoist connects to a heavy-duty line, which runs through multiple pulleys affixed to the bridge. The hoist is able to raise and fall freely through these pulleys. These motors are essential, since they drive the cables to get the hoist to elevate and drop what it needs to. The trolley is also attached to a second rope that travels side to side on the bridge and moves left to right transporting the hoist. This allows the crane to access items in various regions, making it extremely versatile.

The girder cranes are heavy lifting mechanism in construction projects designed to execute various tasks. They can lift and move extremely heavy materials with great precision and safety, which is one of the few key advantages. These cranes are specifically designed to lift heavy loads, so they can easily and rapidly move the heaviest load borne materials (for instance, concrete blocks or steel beams). This feature is essential for construction, where workers make life easier by saving time and effort

One of the other plus points about girder crane components is their versatility. These have wide applications, ranging from large construction sites to medium-scale industrial environments. This means girder cranes can be tailored to serve any workspace, making them suitable for just about every type of job. No matter if you are working on a huge building project or small factory task, girder cranes can be adjusted accordingly to suit your needs.

In addition, using girder cranes can also be cost-effective. They work at greater efficiency for construction projects because they can quickly hoist heavy-duty weights in a safe and efficient manner. Such operational efficiency cut down expenses as well as hours, thus offering girder cranes pay for themselves to any construction or industrial task. All of this means that when projects go well (and in a timely manner), everyone wins.

Broadly speaking, girder cranes can be single girder or double girder. Single girder end carriage crane consist of a single bridge that is carried by a series of runways. Often used in lower working spaces, these cranes have lifting capacities of up to 20 tons. This type of crane has a small design and lightweight which is easy to operate in the limited space.

However, double girder cranes come as two main bridges that are supported by runways. These cranes are capable of lifting and moving loads that can weigh hundreds to thousands of tons, making them suitable for very large construction project or industrial settings. For even the heaviest tasks, double girder cranes can lift loads of 60 tons and higher. This makes them ideal for heavy lifting in large construction projects.

With a variety of product offerings, Toptech caters to a wide array of material Girder cranes needs that range from small workshops to industrial plants of a large scale. Our product range comprises a variety of overhead cranes, gantry cranes and electric hoists, crane components such as end carriage, crane busbars, etc. Toptech is constantly updated with the latest technology and the most innovative designs.

TOPTECH has customized solutions to meet the particular requirements and Girder cranes requirements of our customers. We know the distinct requirements of various industries and provide customized products that align with specific functionality and standards of performance.

The Girder cranes of TOPTECH's engineers allows us to design high-performance and reliable crane systems We incorporate cutting-edge engineering principles and innovative technologies such as intelligent control systems and synchronized lifting techniques into our manufacturing and design processes

TOPTECH offers a wide range of Girder cranes to help our customers get the most out of their products. This includes maintenance, installation, spare parts and technical assistance. We also provide training and consulting to improve operational efficiency and safety.