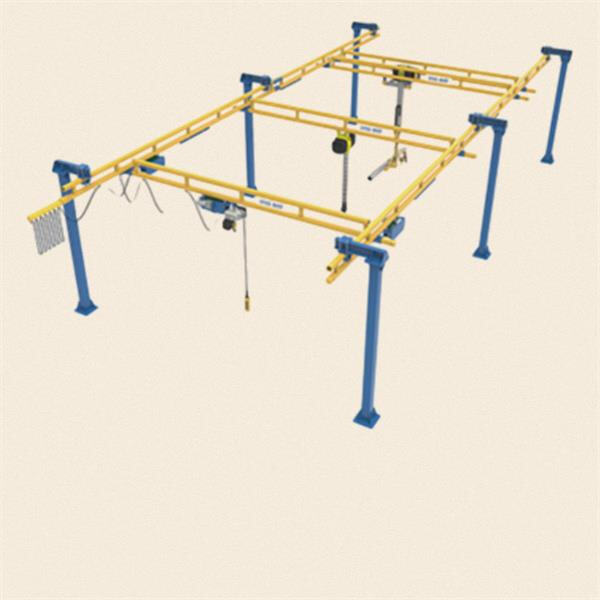

الرافعة ذات العارضة الواحدة هي نوع معين من الرافعات التي تساعدك في نقل الأشياء الثقيلة للتصنيع أو الورشة، كما أن منتج TPTECHOIST مثل كرين eotتم تصميمها بعارضة كبيرة واحدة، يطلقون عليها اسم العارضة التي تمر عبر المساحة التي تحتاج إلى التقاط المواد. توجد مسارات على الجدران أو السقف حيث تتحرك العجلات عند كل طرف من هذه العارضة. يسمح هذا النهج أيضًا للرافعة بنقل العناصر أثناء التحرك أفقيًا، وهو أمر مريح بشكل لا يصدق لنقل الأشياء في الموقع.

تستطيع الرافعة ذات العارضة أن تتولى مناولة المواد دون مشاكل تقريبًا باستخدام فرد واحد. تقوم الرافعة برفع الأشياء الثقيلة بطريقة سهلة وتوفر الوقت مقارنة بالعمال الذين يقومون بمهمة شاقة وخطيرة تتمثل في التحميل اليدوي. وبهذه الطريقة، يتمكن العمال من القيام بالمزيد في وقت أقل، وهذا يساعد الشركة على توفير المال - في حين يتمتع جميع الموظفين ببيئة عمل أفضل.

تعتبر الرافعة ذات العارضة الواحدة قوية للغاية ولكنها لا تزال تؤثر على مساحة أقل بكثير، على غرار رافعة حبل الأسلاك يتم توفيرها من قبل شركة TPTECHOIST. نظرًا لأنها تحتوي على عارضة واحدة فقط، فإن هذا النوع من الرافعات يعمل بشكل جيد أيضًا في الأماكن التي تكون فيها المساحة محدودة. وهذا يجعلها خيارًا ممتازًا للمصانع وورش العمل التي قد لا ترغب في ترك المنطقة غير مستخدمة أثناء عدم التشغيل.

كما أن تركيبها أسهل كثيرًا من الرافعات الأكبر حجمًا والأكثر تعقيدًا. كما أن حجمها يجعلها مضغوطة ولا تتطلب تعديلات كبيرة أو إنشاءات ضخمة في المبنى. وهذا مفيد جدًا للشركات، حيث يقلل من الوقت والمال اللازمين للتركيب.

من ناحية أخرى، يمكن استخدام الرافعات ذات العارضة الواحدة كحل مستقل ميسور التكلفة لرفع بعض الأوزان المتوسطة، تمامًا مثل منتج TPTECHOIST المسمى مصنع الرافعات السلسلةيمكن أن تساعدنا هذه الرافعات في أداء مهام متنوعة بشكل لا يصدق - بدءًا من إنشاء المنتجات إلى بناء الهياكل ونقل العناصر. حجمها الصغير يعني أنها يمكن أن تصل إلى أماكن لا تستطيع الرافعات الأكبر حجمًا الوصول إليها، مما يسمح بمزيد من التنوع.

سيؤدي ذلك إلى خلق بيئة عمل آمنة باستخدام رافعة عارضة واحدة فقط ومن المحتمل أن تسمح للعمال بتغطية مساحة أكبر أثناء العمل، كما أن رافعة حبل سلكي ديماج تم إنتاج هذه الرافعات بواسطة شركة TPTECHOIST. نظرًا لوجود جميع أنواع القيود على الوزن، فإن الرافعات الأصغر حجمًا ترفع أشياءً كبيرة لا يمكن رفعها بقوة عاملة مثل البشر لمنع آلام الظهر الناتجة عن رفع المشتريات الثقيلة. سيؤدي هذا إلى تقليل معدلات الحوادث في العمل ومنع الأشخاص من الإصابة بالأمراض.

كما تعمل الرافعة ذات العارضة الواحدة على جعل العمال أكثر كفاءة، وهو ما يتطابق مع منتج TPTECHOIST طقم رافعة الجسريتيح هذا للعمال نقل المواد الثقيلة بسهولة أكبر، مما يسهل عليهم إنجاز المهمة بشكل أسرع من ذي قبل. ونتيجة لذلك، يمكنهم العمل لساعات أطول وأسرع، وهو أمر جيد لكل من الموظفين والشركة.

بفضل مجموعة متنوعة من عروض المنتجات، تلبي شركة Toptech مجموعة واسعة من متطلبات المناولة بما في ذلك الورش الصغيرة وحتى المصانع الصناعية على نطاق واسع. تتألف مجموعة منتجاتنا من مجموعة متنوعة من الرافعات العلوية، ورافعات الجسر المعلق ذات العارضة الواحدة والرافعات الكهربائية، ومكونات الرافعات مثل العربة النهائية، وقضبان نقل الرافعة، وما إلى ذلك. تواكب شركة Toptech دائمًا أحدث التطورات في التكنولوجيا والتصميمات المتطورة.

نحن نقدم الدعم والخدمات الكاملة لمساعدة عملائنا على الاستفادة القصوى من منتجاتنا. ويشمل ذلك تركيب الرافعات ذات العارضة الواحدة والرافعات الكهربائية، والصيانة، وقطع الغيار، والمساعدة الفنية، كما تقدم TOPTECH خدمات التدريب والاستشارات لتحسين كفاءة العمليات وضمان السلامة، وضمان الأداء الأمثل للمعدات.

تستطيع شركة TOPTECH تصميم حلول مخصصة لتلبية الاحتياجات التشغيلية الخاصة بعملائها. منتجاتنا من الرافعات ذات العارضة الواحدة مصممة لتناسب المتطلبات المحددة لمختلف الصناعات.

تسمح لنا رافعة العارضة الواحدة eot الخاصة بمهندسي TOPTECH بتصميم أنظمة رافعات عالية الأداء وموثوقة. نحن ندمج مبادئ الهندسة المتطورة والتقنيات المبتكرة مثل أنظمة التحكم الذكية وتقنيات الرفع المتزامنة في عمليات التصنيع والتصميم الخاصة بنا