Köprü veya portal vinç olarak da bilinen bir üstten vinç, ağır nesneleri kaldırmak ve taşımak için çeşitli endüstrilerde kullanılan bir endüstriyel makinedir. Bu tür vinçler fabrikalar, depolar ve inşaat alanları gibi her yerde görülebilir. Amaçları, insanların elle kaldırmasına gerek kalmadan nesnelerin ağır taşınmasını kolaylaştırmak ve güvence altına almaktır, bu nedenle tercih edin köprülü vinç parçaları TPTECHOIST'ten. Köprülü Vinçler, her biri vincin düzgün çalışmasında önemli bir rol oynayan bir dizi parçadan oluşur. Bir köprülü vincin ana bileşenlerini öğrenirken, bu güçlü makinenin nasıl çalıştığı ve neden bu kadar değerli olduğu konusunda daha iyi bir anlayış geliştireceğiz.

Troley, bir üstten vincin bir diğer ayrılmaz parçasıdır. Bir ray boyunca hareket eder ve vinçleri bir yandan diğerine taşır. Bu hareket, vincin her yere gidebilmesini ve yükü her yerden kaldırabilmesini sağlar. Troley, ray üzerinde düzgün bir şekilde yuvarlanmasını sağlayan tekerleklere sahiptir. Bu tekerlekler, troley'nin yüksek hızda ve kolayca hareket etmesini sağladığı için çok kullanışlıdır ve bu da tel halatlı vinç TPTECHOIST'ten verimli.

Askı kontrolü ayrıca güvenlik operasyonuna alternatif olarak önemli bir bileşendir. Bu, vinç operatörünün hareketlerini kontrol etmek için kullanırken tuttuğu bir araçtır. Otomatik troley'nin yandan yana hareket etmesini ve ne kadar yukarı veya aşağı hareket etmesini istediğimizi sağlayan askı kontrolü olarak adlandırılır. Ayrıca, herhangi bir şey ters giderse vurulabilen kapatma anahtarları da vardır. Bu Vinç bileşenleri TPTECHOIST'in bu özelliği önemlidir çünkü acil bir durumda operatörün vinci durdurması gerekir ve bu özellik bu konuda operatöre çok yardımcı olur.

İlk olarak, vincin onarımı sırasında hangi belirli parçasının yardımımıza ihtiyacı olduğunu belirlememiz gerekir. Bu, bazen vincin birkaç parçasını yakından incelemek için vincin sökülmesini gerektirebilir. Bu kapsamlı inceleme, ilk bakışta gözden kaçırabileceğiniz şeyleri ortaya çıkarabilir. Sorunlu parçayı seçtikten sonra, en iyi köprülü vinçlerle artık sorun yaşamadığınızdan emin olmak için onarılabilir veya değiştirilebilir, bu nedenle Vinç Güvenlik Cihazı.

Vinçlerimizin optimum etkilerini gerçekleştirmek için, onu uygun şekilde kullanmamız ve bakımını yapmamız oldukça önemlidir. Buna, vincin olması gerekenden fazla ağırlık kaldırmaması için her parçanın iyi çalıştığını kontrol etmek de dahildir. Uçlar ve aşınma kesinlikle güvenlik kurallarına uymalıdır. Vinçleri çalıştırma konusunda eğitim Elektrikli Vinç Sistemi Doğru bir şekilde kullanmak da göz ardı edilmemesi gereken bir şeydir; bu, kaldırma makinesi kullanan tüm kişiler için geçerlidir.

Müşterilerimizin ürünlerimizden en iyi şekilde yararlanmasını sağlamak için elektrikli vinç ve kaldırma makinelerinin kurulumu, bakımı, yedek parçaları ve vinç bileşenleri dahil olmak üzere geniş bir yelpazede yardım ve destek sunuyoruz. TOPTECH ayrıca, operasyonun güvenliğini ve verimliliğini artırmak ve ekipmanın en iyi şekilde performans göstermesini sağlamak için eğitim ve danışmanlık hizmetleri de sunmaktadır.

TOPTECH, müşterilerimizin özel gereksinimlerini ve operasyonel Köprülü Vinç bileşenlerini karşılamak için özelleştirilmiş çözümler sağlayabilir. Farklı endüstrilerin özel ihtiyaçlarına uyacak şekilde yapılmış ürünler sunuyoruz.

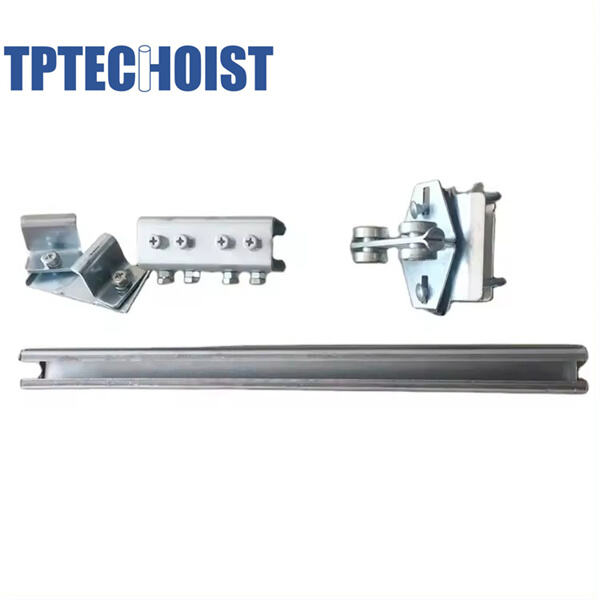

Çeşitli ürün teklifleriyle Toptech, küçük atölyelerden büyük ölçekli endüstriyel tesislere kadar çok çeşitli taşıma gereksinimlerine hitap eder. Ürün yelpazemiz çeşitli üstten vinçler, üstten vinç bileşenleri ve elektrikli vinçler, uç taşıyıcı, vinç barası vb. gibi vinç bileşenlerini içerir. Toptech, teknolojideki en son gelişmeler ve son teknoloji tasarımlar konusunda her zaman günceldir.

TOPTECH'in Köprülü Vinç bileşenleri konusundaki uzmanlığı, güvenilir ve yüksek performanslı, yüksek performanslı ve sağlam vinç sistemleri geliştirmemizi sağlar. Tasarım ve üretim süreci, senkronize kaldırma sistemi ve gelişmiş kontrol sistemleri gibi akıllı kontrol sistemlerinin yanı sıra son teknoloji mühendislik prensiplerini, gelişmiş teknolojileri de içerir.