モデル: PWU

荷重容量:3t -16t

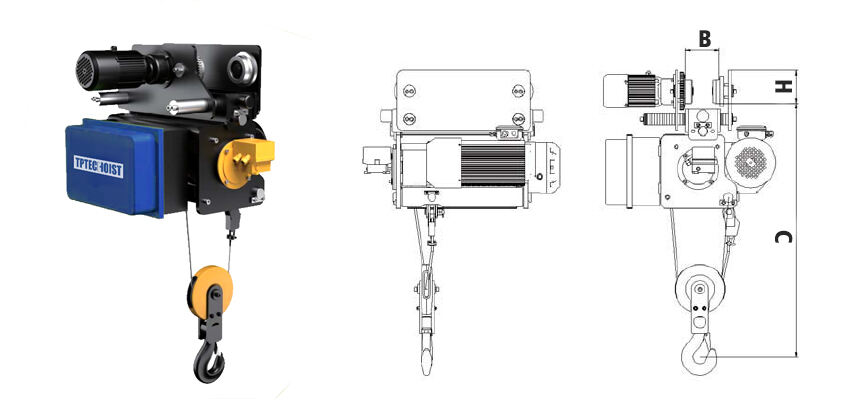

TOPTECHタイプUワイヤーロープホイストは、標準ヘッドルームホイストとも呼ばれています。その横移動トロリーは、露出した減速ギアリングなしで直接駆動のために設計されています。荷重が4または8つの車輪に分散されているため、普通の丸断面ビームを使用してモノレール トラックアプリケーションに使用できます。短いスパンであっても、このホイストを使用して普通の丸断面ビーム上で高負荷クレーンを操作できます。

1. モジュラーデザイン、コンパクトな構造、軽量です。

2. クレーンは低騒音で動作し、作業環境や労働者への妨害を減らします。

3. IP55保護等級で優れた防塵・防水性能を実現し、さまざまな環境での適応性と信頼性が向上します。

4. 全周波数駆動によるクレーンの昇降および横移動は、滑らかで正確な速度制御を確保し、連続的な長時間運転能力を通じて作業効率と安定性を向上させます。

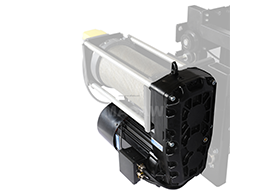

1.トロリー用モーター

IP55保護付きインバーターモーター;スプラインフィット直結駆動密閉走行システム;長寿命で調整が必要ないコンパクトブレーキ。

2.トロリーフレーム

軽量設計;車輪圧力が小さい;コンパクトな構造で作業範囲を広げ、揚程を最適化しました。

3.過負荷制限スイッチ

ワイヤー保持クロスヘッドに統合された電気機械式過負荷保護。中央電子ユニットによる評価。

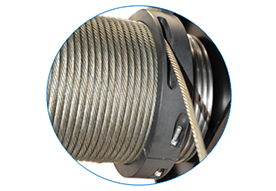

4.ワイヤーロープ

引張強度2160Mpaまでのガルバニズドワイヤーロープ;ナイロンロープガイドでスムーズなロープ導入;

厳しい環境下でも同様です。

5.電気パネル

モジュラーデザイン、外装保護クラスIP55;シュナイダーエレクトリックのコンタクターを採用し、クイックアダプターを使用。

6.揚重モーター

耐久性に優れたギヤと一生の潤滑油を使用した3段階のヘリカルギヤボックスが含まれています;サーマルコンタクト、DCディスクブレーキ。

7.高さ制限スイッチ

上下の位置での標準的な緊急カットオフ用に4つの接点セットを搭載;

速いから遅いへのカットオフにより追加の安全性が向上します。

8.フックブロック

DIN 15401規格のRSNフック、強度クラスT;ノッチ付きラッチが堅固な接触を改善し、横方向の力に対する耐性を高めます。

| 荷重 kg | FEM仕様クラス | ロープ配置 | 昇降モーターKW | 揚げ速度 (m/分) | トロリー用モーターKW | B (mm) | H (mm) | C (mm) |

| 3000 | 2M | 2/1 | 3.2 | 0~5 | 0.4 | 110から150 | 135 | 1050 |

| 3000 | 2M | 2/1 | 4.5 | 0~8 | 0.4 | 110から150 | 135 | 1050 |

| 5000 | 2M | 2/1 | 4.9 | 0~5 | 0.4 | 110から150 | 135 | 1350 |

| 5000 | 2M | 2/1 | 7.5 | 0~8 | 0.4 | 110から150 | 135 | 1350 |

| 5000 | 2M | 4/2 | 4.9 | 0~5 | 0.4 | 110から150 | 135 | 1350 |

| 5000 | 2M | 4/2 | 7.5 | 0~8 | 0.4 | 110から150 | 135 | 1350 |

| 10000 | 2M | 4/2 | 9.5 | 0~5 | 0.4*2 | 130-180 | 155 | 1500 |

| 10000 | 2M | 4/2 | 12.5 | 0~7 | 0.4*2 | 130-180 | 155 | 1600 |

| 16000 | 2M | 信頼 の 源 と なる | 12.5 | 0~3.5 | 08*2 | 130-180 | 155 | 1700 |

注記:

1. 台車の速度: 0~20m/分 VFD

2. 事前の通知なしに変更される場合があります。最終的な技術データは、私たちのマニュアルおよび寸法図に記載されています。

ダブルギダー屋上橋式クレーン

FEM規格単一グライダー懸垂クレーン

オーバーヘッドクレーン用ワイヤーロープホイスト